Start up with your product samples from Urethane Casted parts and save your investments until the designs have fulfilled the requirements. Increase the confidence in your design before committing to mass production.

Save product development time by having multiple samples within 1 week. We can provide 10pcs. within 5-7 working days. *(*if without master pattern, lead time will be longer)

Urethane Casting can provide parts with tolerance up to 1/0.15mm per 100mm. We can produce fine features up to 0.5mm width and depth.a

With our vacuum casting machine, parts up to 450 x 450 x 450mm can be produced in one(1) casting. Parts with minimum thickness of up to 1.5mm can be guaranteed.a

A selection of materials that simulate engineering plastics such as ABS, Polypropelene, Polycarbonate and rubber of different hardness, simulations of designs for different applications will be more accurate with the right material

Cast your parts with color you need. Reduce leadtime from painting

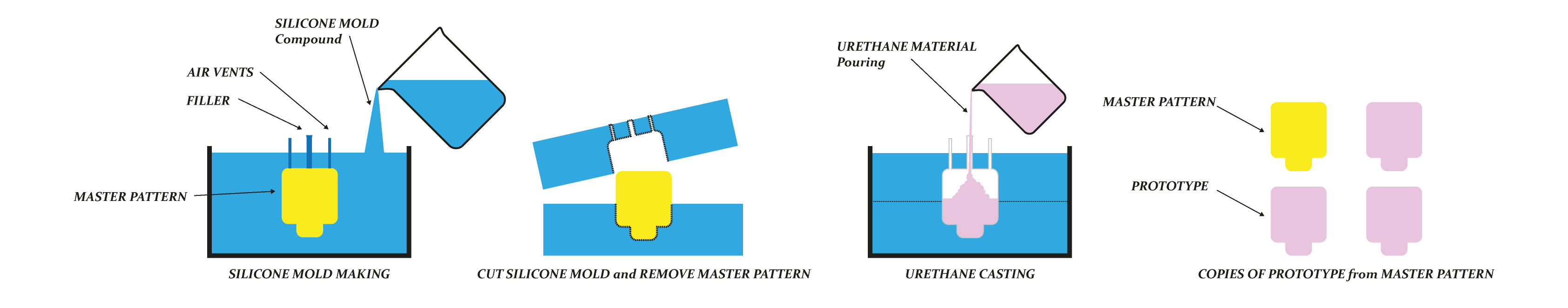

- A mold made out of Silicone with a cavity that follows the pattern to be reproduced.

- It is commonly known as Room Temperature Vulcanizing or RTV.

- A great solution to making parts in small batches or low-volume production runs without initial high investment inherent with injection molding/press dies.

- Offers high part detail retention as fine as fingerprint marks can be copied in the silicone mold.

- Can be used to reproduce around 10 – 50 units per mold, depending on material and design complexity.

- Insert molding and over-molding is also possible using this method.

- Using a thermosetting plastic material (similar to epoxy) to create multiple copies of the master pattern.

- Together with the Silicone mold, parts can be produced with urethane plastic or urethane rubber materials that offer a wide range of mechanical, visual and electrical properties.

- Materials with UL and RoHS compliance are also available.

- Post processing such as machining and painting can also be done to urethane casted parts.

- Urethane casted parts offer suitability to be used as final material for your products.

- Typically has lower cost than 3D printing for parts greater than 10 units.

- Has an advantage over Injection molding, where investment of initial tooling is necessary, for volumes less than 1000 units.

It is the item that will be manufactured or reproduced.

It can be made from machined wood, plastic, metal, molded clay, or even 3D printed parts, depending on the complexity of the design.

It can also be an existing part that you want to reproduce.